The sign convention for m requires that it is positive if the diffracted ray lies to the left (counter-clockwise side) of the zeroth order and negative if it lies to the right (the clockwise side).

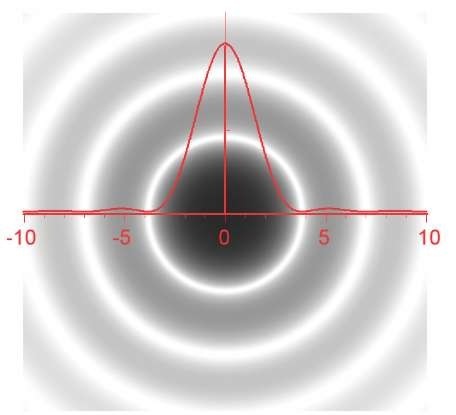

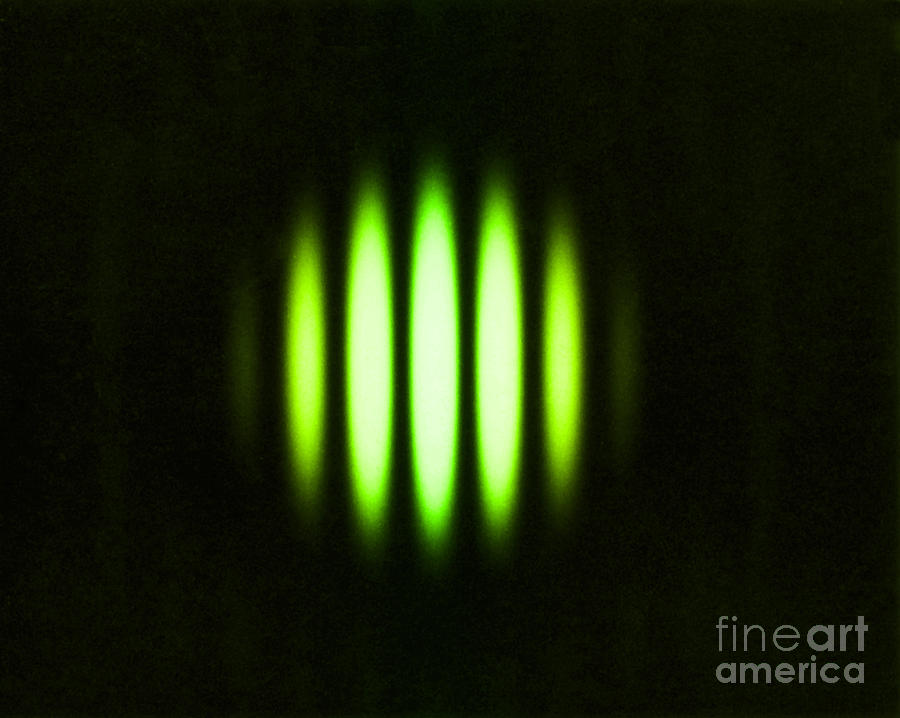

and β 0 are equal and opposite, resulting in the light simply being reflected, i.e., no diffraction. In the grating equation, m is the order of diffraction, which is an integer. If β m is on the opposite side of the grating normal from α, its sign is opposite. These angles are measured from the grating normal, which is shown as the dashed line perpendicular to the grating surface at its center. Light of wavelength λ is incident at an angle α and diffracted by the grating (with a groove spacing d G) along a set of angles β m. The blaze wavelength is the wavelength for which the grating is most efficient.įigure 3 illustrates this diffraction. This involves modifying the groove profile, including facet angles, shapes and/or depths. To optimize this efficiency for a single wavelength, a procedure known as blazing is performed. Maximizing the efficiency into a single order, typically the first order, is often desired to ensure increased light collection. When monochromatic light strikes a grating, a fraction of it is diffracted into each order (termed its efficiency). In addition to the spacing of the grooves, the groove profile (see Figure 2) plays a key role in the performance of a grating. The groove spacing determines the angles at which a single wavelength will constructively interfere to form diffracted orders (see below), which are equivalent to the intensity peaks shown in Figure 1. This is more commonly reported as the groove density ( G), which is the reciprocal of d G, e.g., typical gratings have G values between grooves per mm. A typical diffraction grating (see Figure 2) consists of a large number of parallel grooves (representing the slits) with a groove spacing (denoted d G, also called the pitch) on the order of the wavelength of light. Gratings can be transmissive, like the multi-slit aperture, but they can also be reflective where the grooved surface is overcoated with a reflecting material such as aluminum. It provides angular dispersion, i.e., the ability to separate wavelengths based on the angle that they emerge from the grating. Consequently, surfaces with well-defined slit locations can be used to direct light of certain wavelengths into specific directions.Ī diffraction grating is essentially a multi-slit surface. These directions are strongly dependent on both the slit spacing and wavelength of the incident light. Similarly, when light passes through an opaque screen consisting of multiple elongated apertures (or slits) with a fixed spacing between them, the emerging wavefronts constructively interfere to produce a diffraction pattern with intensities peaked in certain directions as shown in Figure 1. The resulting intensity distribution is called a diffraction pattern. This diffraction phenomenon occurs because of interference (see Laser Light Characteristics on coherence for details) between different portions of the wavefront. Since light is an electromagnetic wave, its wavefront is altered much like a water wave encountering an obstruction.

When light encounters an obstacle such as an opaque screen with a small opening (or aperture), the intensity distribution behind the screen can look much different than the shape of the aperture that it passed through.

0 kommentar(er)

0 kommentar(er)